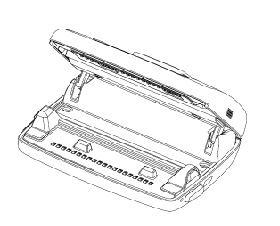

The briefing involves the design of an innovative medicine dispenser to ensure the correct administration of medicines and control by relatives or assistance staff, ensuring the intake of the drug in certain times and days.

The device must contain a mechanical electronic system for gripping the blister that communicates by means of a dedicated software with the Apps contained in the mobile phones of the persons concerned.

The product must be handy, easy to use for loading medicines and with a simple and effective user interface.

Product development progresses by linking the design, IT, electronics, carton, packaging and mechanical departments.

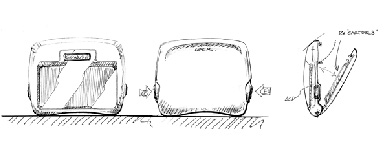

By supporting the customer in a careful analysis of the context of use of the article, the first conceptual sketches of the system.

The selected concept is then deepened in all its aspects characterizing functionality, structure and conformation.

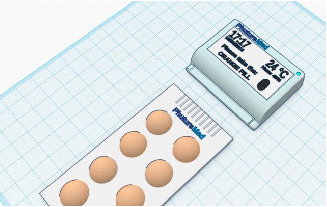

The technical volumes are modeled which must contain all the locking, electronic and functional components of the device. The draft of the card containing the electronic tracks is built and on which the medicine blister will be placed.

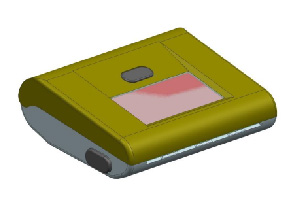

The article is modeled in 3D following the proposed aesthetic concepts and respecting the functional and mechanical constraints imposed.

For some aesthetic and finishing checks we prepare rendered views of the model.

The functional heart underlying the entire system is prototyped and tested very quickly.

The validity of the concept is confirmed and the foundations are laid for further progress of the project.

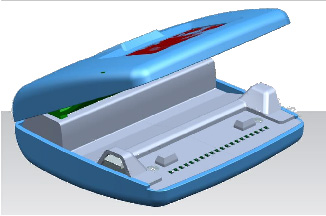

The entire article is prototyped to study in detail its functionality, aesthetic details, any assembly difficulties and / or use.

The article is definitively validated.

The article is definitively industrialized. All details are optimized for the production of the article; most of the components will be made with injection molding, others will be supplied externally.

The components, made of different plastic materials, must match perfectly to ensure comfort and a professional appearance.

Discover the services we offer and request a consultation or an appointment to find out what we can do to create and design your product

Presenteremo l’importanza della misurazione degli impatti ambientali il 26 Settembre 2023

Ecomondo – Digital Green Week