The briefing involves the design of a system for the automatic impregnation of cloths for professional cleaning of environments (offices, hospitals, hotels).

The main requests were the following:

– regulation of the quantity of detergent liquid dispensed in order to optimize and reduce consumption

– elimination of the preparatory phase of the cleaning cloths and automation of the impregnation process in order to reduce working times

– facilitation ergonomics of the actions to be performed

– ease of cleaning the item

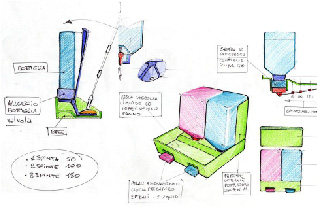

By supporting the customer in a careful analysis of the context of use of the article, the first conceptual sketches of the system are developed. The selected concept is then deepened in all its aspects characterizing functionality, structure and conformation.

The functional core is optimized in terms of size, quantity of liquid dispensed, number and cost of components, assembly; subsequently it is prototyped and tested again. Prototype verification is essential for an article where functionality will guarantee its success.

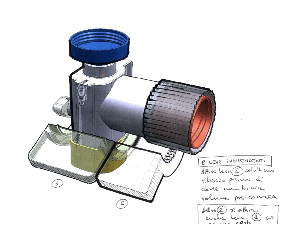

The functional heart underlying the entire system is prototyped and tested very quickly. The validity of the concept is confirmed and the foundations are laid for the further progress of the project. The basic concept consists of a chamber that contains the detergent liquid, which is discharged into a tray by operating a lever. The cloth is placed in the tray to moisten.

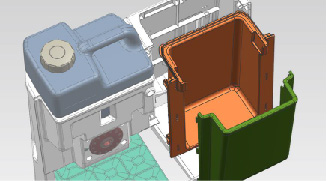

The entire machine is further defined in its component elements, always taking into account the ergonomic and cleaning aspects. In addition, some aspects relating to industrialization also begin to have a certain importance, such as the number of component parts and their size; things that will determine the final cost of the item.

The entire article is prototyped to study in detail its functionality, aesthetic details, any difficulties in assembly and / or use. The article is definitively validated.

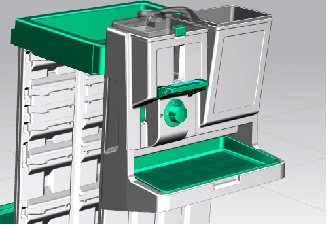

The article is definitively industrialized. All details are optimized for the production of the article; most of the components will be made with injection molding, others with blow molding, others will be supplied externally. All components, made of different plastic materials, must match perfectly to ensure a professional appearance, maximum cleanliness of the item and the watertight seal of the gaskets.

The product is a machine that allows the dispensing of an adjustable amount of detergent liquid for the impregnation of cloths to be used for cleaning floors in various types of environments.

Discover the services we offer and request a consultation or an appointment to find out what we can do to create and design your product

Presenteremo l’importanza della misurazione degli impatti ambientali il 26 Settembre 2023

Ecomondo – Digital Green Week